Local Area Networks: Powering Manufacturing and Automation

Tags: Automation, Infrastructure, Manufacturing, LAN,

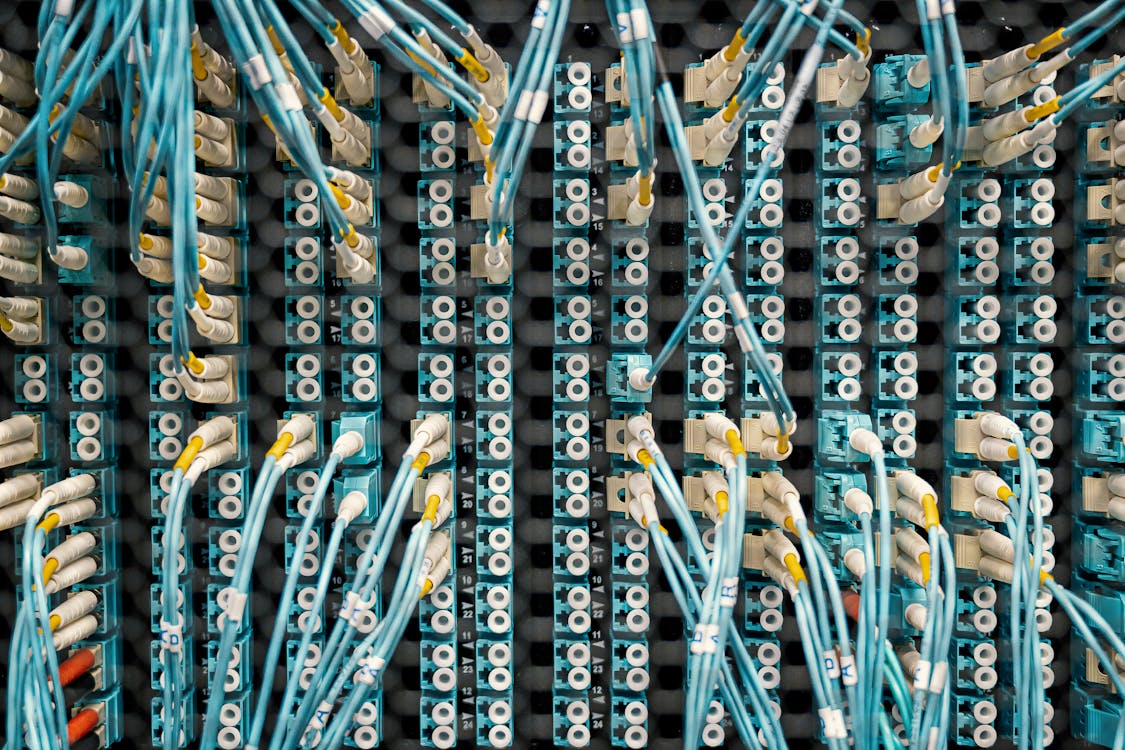

In the rapidly evolving landscape of manufacturing and automation, Local Area Networks (LANs) have emerged as a backbone for modern industrial operations. LANs in manufacturing settings are crucial for facilitating communication between various devices, systems, and departments, enhancing efficiency, and supporting advanced automation processes. This article delves into the role of LANs in manufacturing and automation, exploring their significance, applications, and the benefits they bring to these sectors.

The Role of LANs in Manufacturing and Automation

LANs provide a network infrastructure that allows for the seamless transfer of data within a limited area, typically a factory floor or an industrial plant. In manufacturing and automation, LANs are used to connect various components such as computers, PLCs (Programmable Logic Controllers), sensors, and machinery to a central network. This connectivity is fundamental for the coordination and control of automated processes and for real-time data exchange.

Facilitating Communication and Data Transfer

- LANs enable devices and systems to communicate with each other and with central control units. This communication is essential for monitoring and controlling automated manufacturing processes, where precise timing and synchronization are critical.

- In automated assembly lines, LANs ensure that machinery operates in unison and that production data is continuously relayed to control centers for monitoring and analysis.

Integration with Industrial Internet of Things (IIoT)

- The integration of LANs with IIoT devices is transforming manufacturing floors into smart, interconnected environments. Through LANs, IIoT devices can collect and transmit data, contributing to more informed decision-making and process optimization.

- This integration facilitates predictive maintenance, energy management, and the implementation of advanced manufacturing techniques such as digital twins and additive manufacturing.

Applications of LANs in Manufacturing and Automation

Process Control and Monitoring

- In process control applications, LANs are used to connect sensors and control systems that regulate manufacturing processes. They provide the necessary bandwidth and speed for the real-time transfer of control data, ensuring processes are conducted efficiently and without interruption.

- For instance, in the chemical industry, LANs facilitate the real-time monitoring and adjustment of process variables like temperature, pressure, and flow rates, critical for maintaining product quality and safety.

Material Handling and Logistics

- LANs play a vital role in material handling and logistics within manufacturing facilities. Automated guided vehicles (AGVs), conveyors, and robotic arms are connected via LANs, enabling synchronized operations for the movement and handling of materials.

- This connectivity is crucial for optimizing the logistics flow, reducing material handling time, and minimizing the potential for errors.

Quality Control and Inspection

- In quality control, LANs enable the connection of inspection devices and cameras to central systems for real-time quality assessment. This setup allows for immediate feedback and correction of issues, maintaining high-quality standards in the manufacturing process.

Benefits of Using LANs in Manufacturing and Automation

Enhanced Efficiency and Productivity

- The primary benefit of LANs in manufacturing and automation is the significant enhancement in efficiency and productivity. By enabling real-time communication and data transfer, LANs allow for faster decision-making and more agile responses to changing conditions on the manufacturing floor.

- This connectivity leads to shorter production cycles, reduced downtime, and a more streamlined manufacturing process.

Scalability and Flexibility

- LANs offer scalability and flexibility, allowing manufacturing facilities to easily expand their network as their operations grow. New devices and systems can be integrated into the network with minimal disruption, providing a scalable solution that grows with the business.

- The flexibility of LANs also supports the implementation of customized manufacturing processes, catering to the evolving demands of the market.

Cost-Effectiveness and Improved Collaboration

- Implementing a LAN in a manufacturing setting can lead to cost savings by reducing manual labor, minimizing errors, and improving overall operational efficiency.

- LANs also promote better collaboration between different departments, such as production, quality control, and maintenance, by providing a unified platform for data sharing and communication.

Conclusion

Local Area Networks have become indispensable in the manufacturing and automation sectors, driving advancements in process control, efficiency, and smart manufacturing practices. As manufacturing processes become increasingly complex and data-driven, the role of LANs in providing reliable, fast, and secure communication is more critical than ever. The continued evolution of LAN technology, coupled with the integration of new digital tools and IIoT devices, is set to further enhance the capabilities and efficiency of manufacturing operations. In the era of Industry 4.0, LANs stand as a key technological component, supporting the transformation of traditional manufacturing floors into interconnected, intelligent, and highly efficient production environments.